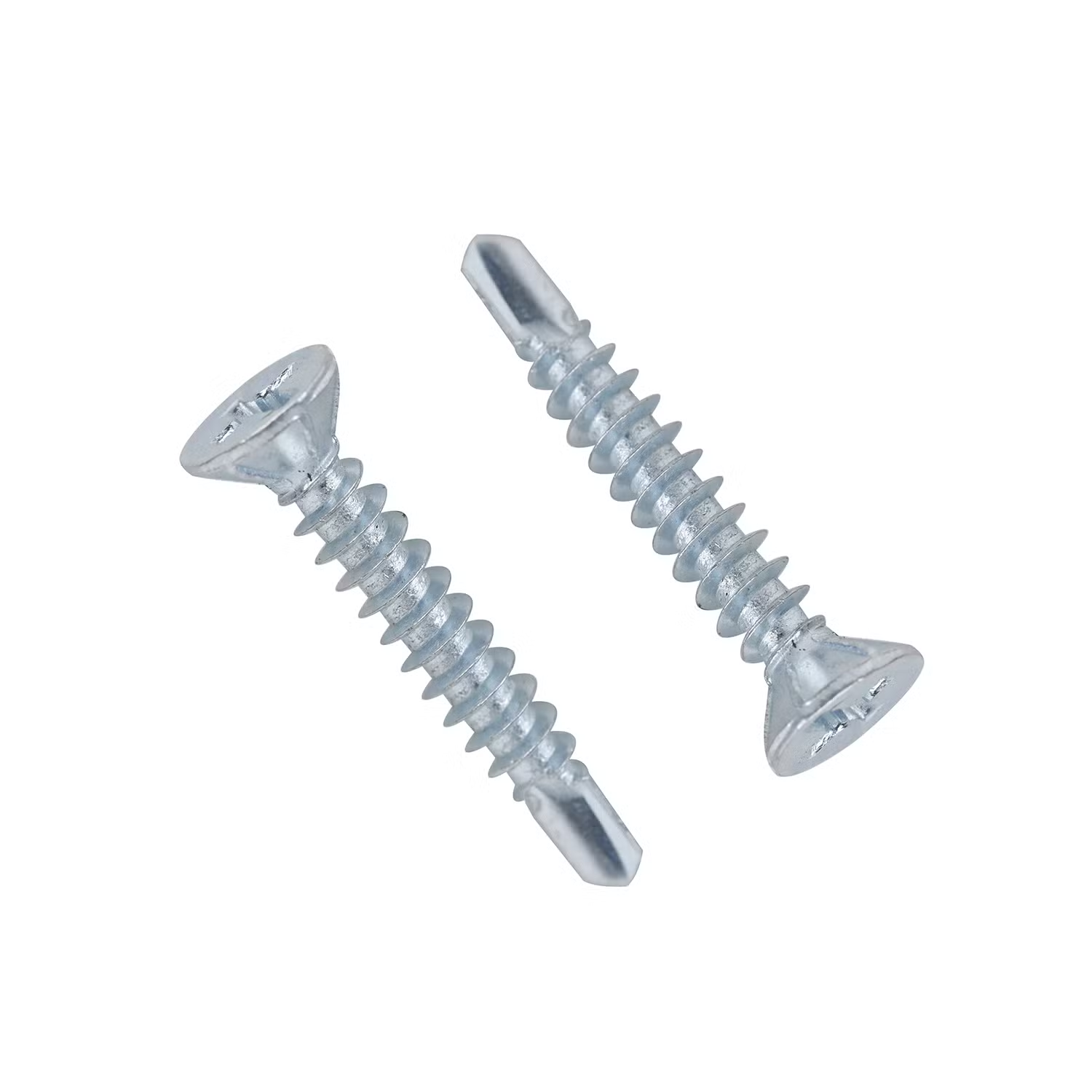

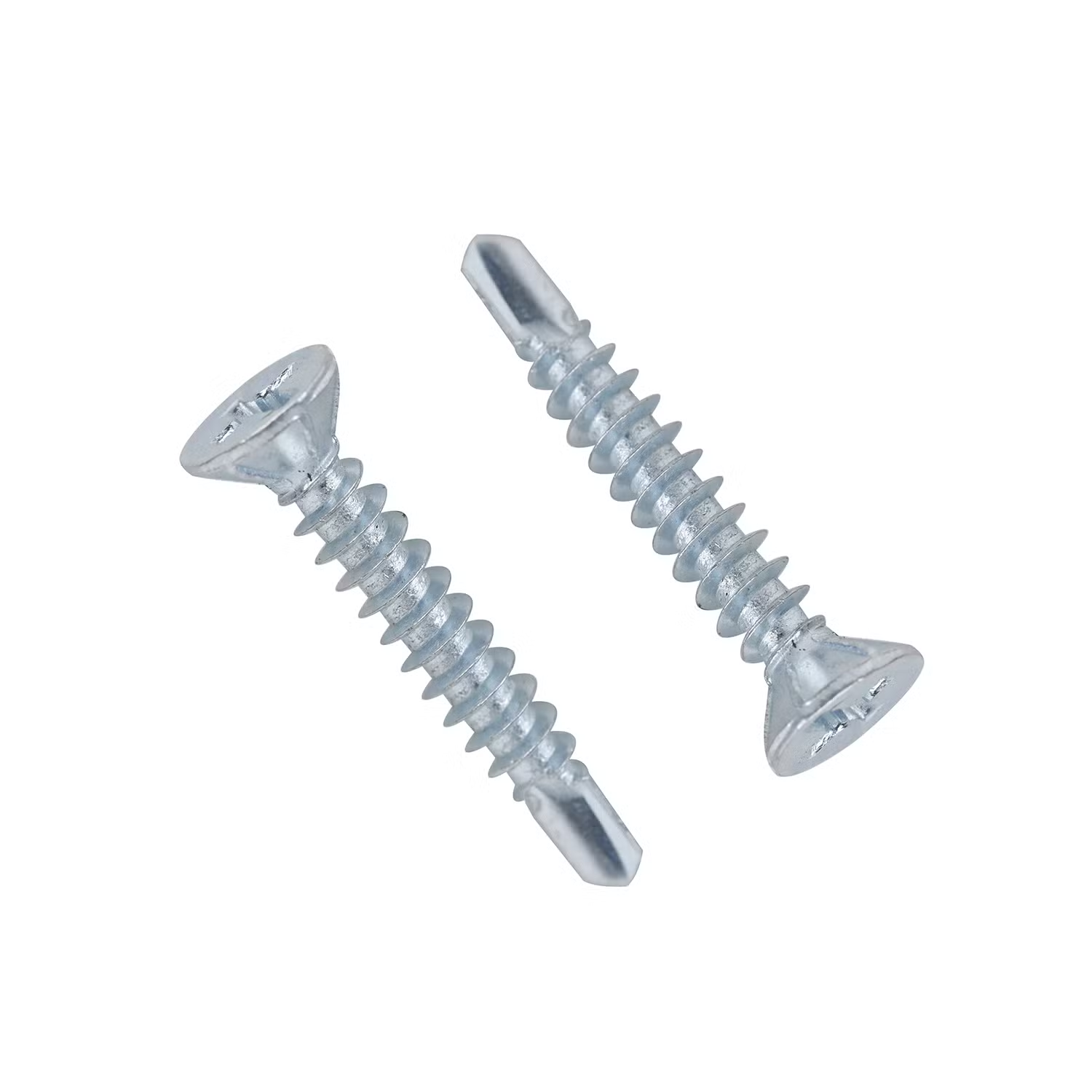

410SS #3 Point Self-Drilling Stainless Steel Screw - PHIL Flat Tek

Introducing the 410SS #3 Point Self-Drilling Stainless Steel Screw - PHIL Flat Tek, the ultimate solution for your fastening needs. Picture this: you're effortlessly driving this high-quality screw into tough stainless steel, all while enjoying its corrosion resistance and superior durability. With its PHIL Flat Tek design, this screw is not just a fastener, but a game-changer for your projects. Upgrade your toolbox today and experience the power of the 410SS #3 Point Self-Drilling Stainless Steel Screw - PHIL Flat Tek!

Send your inquiry

Efficient Self-Drilling Stainless Screws

Get the job done right with our PHIL FLAT TEK #3 Point Self-Drilling Stainless Steel Screw, perfect for all your self-tapping needs. Made with high-quality stainless steel 410, this screw is durable and long-lasting. Available in small box, plastic box, carton, or pallet packaging for your convenience.

● Superior Stainless Steel Construction

● Versatile Surface Treatments Available

● Convenient Packaging Options

● Customizable Specifications

Product Display

Efficient, Precise, Durable, Versatile

Efficient Self-Drilling Stainless Screw

The PHIL FLAT TEK 410SS #3 Point Self-Drilling Screw is made from high-quality stainless steel 410, providing excellent corrosion resistance and durability. With its self-tapping function, this screw offers easy and efficient installation on various materials. The screw's surface treatment options include zinc plating, nickel plating, passivation, and electrophoresis, ensuring long-lasting performance in different environments.

◎ Durable

◎ Self-tapping

◎ Versatile

Material Introduction

The PHIL FLAT TEK 410SS #3 Point Self-Drilling Stainless Steel Screw is made of high-quality stainless steel 410, ensuring durability and resistance to corrosion. With its self-tapping design, this screw is perfect for use in a wide range of applications. It is a reliable and sturdy fastening solution for both indoor and outdoor use, making it a versatile choice for various projects.

◎ 410 Stainless Steel

◎ Self-Drilling

◎ Corrosion-Resistant

Application Scenario

FAQ