Self-Tapping Screws: Essential Points from Leading Manufacturers

Introduction

What Are Self-Tapping Screws and Why Are They Preferred?

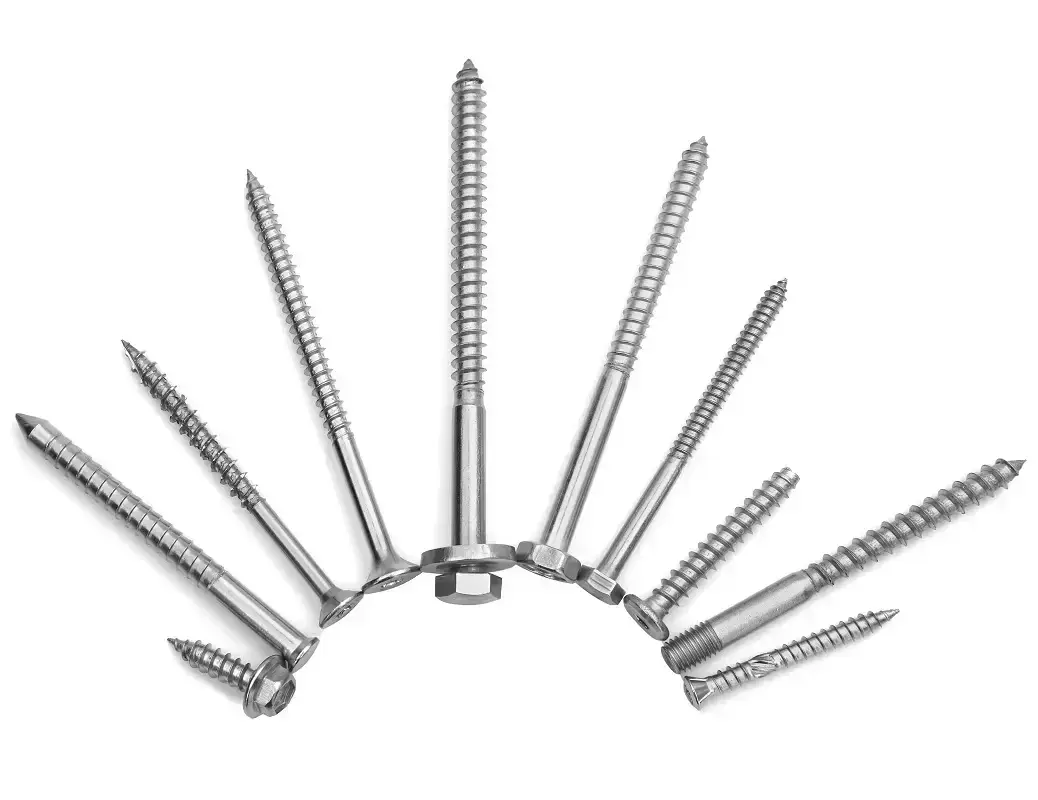

Self-tapping screws, also known as self-drilling screws, are a type of fastener that integrates the tapping mechanism into the screw itself. They come in various sizes, materials, and head types, making them versatile for different applications. The primary advantage is their convenience; they save time and effort by eliminating the need for additional tools during installation.

Self-tapping screws are preferred over conventional screws in scenarios where time is a constraint or where tools are limited. They are commonly used in construction, woodworking, automotive, and industrial settings. Available in materials like steel, stainless steel, aluminum, and zinc, these screws cater to diverse requirements, ensuring durability and compatibility with different surfaces.

How Do Self-Tapping Screws Work?

The mechanism behind self-tapping screws is both innovative and efficient. When inserted into a material, the screw starts rotating and drilling into the wood or metal simultaneously. This dual action continues until the desired depth is reached, after which the screw advances fully into the material, creating a pilot hole with a smooth finish.

This process is seamless and reduces the risk of stripping the screw, which is a common issue with traditional screws. The mechanism is designed to handle various materials and sizes, ensuring consistent performance across different applications.

Common Issues and Solutions in Using Self-Tapping Screws

Despite their advantages, self-tapping screws are not without challenges. Common issues include insufficient torque, leading to improper installation, and compatibility problems with certain materials. Over-tightening can cause the screw to protrude beyond the pilot hole, affecting the finish.

To mitigate these issues, it's crucial to follow manufacturer guidelines for torque specifications and material compatibility. Applying the correct torque ensures the screw is inserted properly without exceeding the desired depth. Additionally, selecting the right screw type for the material prevents potential issues during installation.

Self-Tapping Screw Selection: Key Considerations

Choosing the right self-tapping screw involves several considerations. The primary factors include torque requirements, material compatibility, environmental conditions, and the need for precision. Understanding the torque specs helps in selecting the appropriate screw. Checking material compatibility charts ensures the screw will work well with the chosen material.

Environmental factors such as temperature and humidity also play a role, as some materials degrade under certain conditions. Manufacturers often provide guidelines on how to store and handle screws to maintain their quality. It's essential to follow these recommendations to extend the lifespan of your screws.

Case Studies: Real-World Applications and Insights

Real-world applications highlight the effectiveness of self-tapping screws. In a recent construction project, a homeowner installed self-tapping screws in wooden beams, achieving a seamless fit without additional tools. This resulted in a faster project completion and a cleaner finish.

In an automotive context, a mechanic used self-tapping screws to install bolts in a car frame, saving time and ensuring precise alignment. Another industrial application involved a manufacturer using self-tapping screws in their machinery assembly, which not only accelerated production but also reduced the risk of tooling errors.

Comparing Self-Tapping Screws from Leading Manufacturers

Leading manufacturers like Corby, Pro-Tite, and J.B. Weld offer a range of self-tapping screws tailored to different needs. Corby's screws are known for their durability and precision, while Pro-Tite offers a variety of options for different materials and applications. J.B. Weld is recognized for its superior quality and extensive product range.

Customer reviews and ratings highlight the performance of each manufacturer. Corby's screws often receive high marks for consistency and reliability, whereas Pro-Tite is praised for its availability and affordability. J.B. Weld is frequently mentioned for its superior quality and durability.

Tips for Choosing the Right Self-Tapping Screw Manufacturer

Selecting the right manufacturer involves considering factors like reliability, quality, and customer support. Reading reviews and checking ratings can help identify trustworthy suppliers. Ensuring the manufacturer meets industry standards and provides adequate warranties is crucial for long-term use.

When evaluating options, it's important to compare product features, such as torque ranges and material compatibility. Manufacturers who offer customization options can cater to specific project needs, enhancing the overall efficiency.

Conclusion

Self-tapping screws are an essential tool in any project requiring precision and convenience. By understanding their fundamentals, selecting the right screws, and considering material compatibility, you can maximize their benefits. Whether you're a homeowner, a professional, or a DIY enthusiast, self-tapping screws offer a reliable solution for a variety of tasks.

Looking ahead, as technology advances, new self-tapping screw options will continue to emerge, ensuring they remain a vital part of any toolbox. By prioritizing quality and considering the right manufacturer, you can ensure your projects not only succeed but also last a lifetime.