How to Save Time and Get Professional Results with Self-Tapping Screws

Self-tapping screws are a game-changer for anyone looking to streamline their projects and achieve professional results efficiently. These screws are designed to be simple yet effective, offering a seamless solution for attaching materials without the hassle of a pilot hole. Whether you're a DIY enthusiast or a professional contractor, self-tapping screws can save you time and deliver a polished finish. In this guide, well explore the benefits of self-tapping screws, how to choose the right ones, and provide tips for using them effectively in your next project.

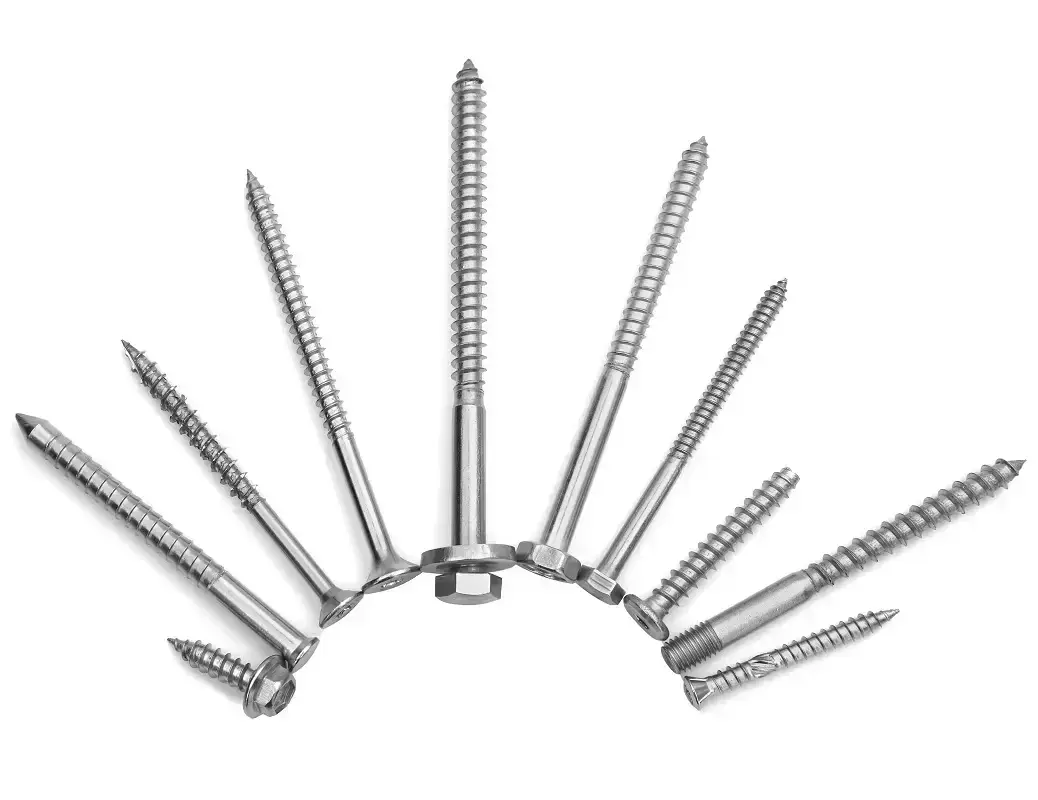

What Are Self-Tapping Screws, and How Do They Work?

Self-tapping screws are a type of screw that, once driven into a material, insert themselves into the wood or metal with minimal or no pilot hole drilling. The name comes from their ability to "tap" themselves into place, eliminating the need for a separate pilot hole. This makes them ideal for situations where you want to save time and avoid the mess of drilling.

The mechanism behind self-tapping screws is designed to ensure a tight, secure fit. When you drive the screw into a surface, the thread of the screw interacts with the material, creating a pilot hole as it goes. Once the screw reaches the desired depth, it locks into place, holding the material in position without any additional steps. This process is much faster and easier than traditional screw installation, which requires drilling a pilot hole and then tapping the screw in.

One of the key advantages of self-tapping screws is their versatility. They work well in a variety of materials, including wood, metal, drywall, and even concrete. Whether you're hanging a picture frame, installing a shelf, or attaching a piece of cabinetry, self-tapping screws can handle it. They are also available in a wide range of sizes, so you can choose one that fits your project needs perfectly.

Choosing the Right Self-Tapping Screw for Your Project

Selecting the correct self-tapping screw is essential to ensure your project is successful and meets professional standards. Here are some factors to consider when choosing screws for your project:

Material Type: Different materials require screws of different sizes and thread strengths. For example, wood requires screws with a certain thread size to avoid splitting, while metal requires stronger screws to prevent bending.

Thread Size: The thread size of your screw must match the material you're screwing into. A screw with a too-small or too-large thread size can cause the screw to bind or not hold properly.

Length: The length of the screw must be sufficient to reach the desired depth in the material. If the screw is too short, it may not reach the surface where it needs to be secured.

Finish and Grade: The finish and grade of the screw must match the surface you're working with. For example, screws used on drywall should be compatible with the finish of the drywall to avoid peeling or chipping.

By carefully considering these factors, you can select self-tapping screws that are tailored to your project, ensuring a professional finish and efficient installation.

Common Applications and Use Cases for Self-Tapping Screws

Self-tapping screws are incredibly versatile and can be used in a wide range of applications. Here are some common use cases where self-tapping screws are the perfect choice:

Attaching Drywall: Self-tapping screws are ideal for securing drywall panels to studs. They provide a clean, flush joint and eliminate the need for a pilot hole.

Installing Cabinets and Drawers: When building or assembling cabinets, self-tapping screws are a quick and easy way to attach the drawers to the fronts of the cabinets.

Assembling Furniture: Many pieces of furniture, such as shelves, trunks, and drawer pulls, use self-tapping screws for assembly. They make the process faster and more efficient.

Building Woodworking Projects: Whether you're making furniture, shelves, or picture frames, self-tapping screws are a reliable choice for attaching pieces together.

Fixtures and Tools: Self-tapping screws are commonly used in tools and fixtures, such as vise grips, clamps, and toolboxes, to attach small parts securely.

Concrete and Masonry: Self-tapping screws are also used in masonry and concrete projects, such as attaching tiles or bricks to a wall.

These are just a few examples of the many applications where self-tapping screws are the perfect choice. Their versatility and ease of use make them a valuable tool for any project.

Tips for Efficient and Precise Use of Self-Tapping Screws

Using self-tapping screws efficiently and precisely can make the difference between a quick project and one that takes longer than expected. Here are some tips to help you get the most out of self-tapping screws:

Use the Right Tool: To avoid mistakes and save time, use a drill with a self-tapping bit. These bits are specifically designed to work with self-tapping screws and ensure a clean installation.

Line Up the Screw Correctly: Before driving the screw, take a moment to visualize where it will go and ensure that it aligns perfectly with the material youre working with. This will help you avoid driving the screw in the wrong direction or at an angle.

Apply the Right Amount of Torque: Over-torquing the screw can cause it to bend or break, while under-torquing may result in a loose fit. Use a torque wrench to apply just enough force to ensure the screw is secure but not excessively tight.

Work in a Well-Lit Area: Driving screws in a dimly lit area can make it difficult to see where youre going. Work in a well-lit area to ensure accuracy and prevent mistakes.

Clean Up After Yourself: Once the screw is in place, remove any excess debris from the hole. This will make future installations easier and keep your workspace tidy.

By following these tips, you can use self-tapping screws with confidence, ensuring your project stays on track and meets professional standards.

Case Study: A Professional Carpenters Perspective on Self-Tapping Screws

Imagine youre a professional carpenter working on a custom cabinetry project. Youve spent hours cutting and shaping the wood, and now its time to assemble the pieces. Instead of using traditional screws, you decide to try self-tapping screws for the first time.

At first, youre a bit nervous about the new product. Youve heard mixed things about self-tapping screws from other carpenters, and youre not sure if theyll live up to the hype. But youve read that theyre faster and more efficient, so you give it a try.

You start by marking the locations for the screws and then drill pilot holes. But instead of tapping the traditional screws, you use self-tapping screws. The first screw goes in smoothly, and youre impressed by how neatly it fits. You continue installation, and each screw goes in without any issues. You notice that the screws hold the pieces together tightly, and theres no risk of the screws binding or coming loose.

After completing the project, youre shocked at how much time you saved compared to using traditional screws. You didnt have to worry about drilling pilot holes or tapping the screws afterward. The finished product looks professional, and youre confident that it will hold up over time.

This case study highlights the efficiency and reliability of self-tapping screws, proving that they can be a valuable tool for professional contractors.

Comparative Analysis: Self-Tapping Screws vs. Other Fastening Solutions

While self-tapping screws are a great option for many projects, there are other fastening solutions to consider. Lets compare self-tapping screws with traditional nails, traditional screws, and rivets to determine when self-tapping screws are the best choice.

Nails: Nails are great for holding light materials like paper or fabric, but theyre not ideal for heavier materials like wood or metal. They also require a large hole to be driven into the material, which can be time-consuming and frustrating.

Traditional Screws: Traditional screws require a pilot hole to be drilled before they can be tapped into place. While they provide a secure fastener, the process of drilling the pilot hole adds time and can be inconvenient, especially for delicate materials.

Rivets: Rivets are ideal for attaching metal components, but they require a specific type of drill bit and can be difficult to install if the surfaces arent clean. They also dont work well for attaching materials like wood or drywall.

Self-tapping screws offer a convenient and efficient alternative to these options. They eliminate the need for drilling pilot holes, provide a secure fastener, and are suitable for a wide range of materials. Whether youre working with wood, metal, or drywall, self-tapping screws are a versatile and reliable choice.

Enhancing Your Projects with Self-Tapping Screws

Self-tapping screws are a game-changer for anyone looking to streamline their projects and achieve professional results. Their ability to eliminate the need for pilot holes makes them faster and easier to use, while their secure fastening ensures a polished finish. Whether youre a DIY enthusiast or a professional contractor, self-tapping screws can help you get the job done efficiently.

By following the tips outlined in this guide, you can use self-tapping screws with confidence, saving time and delivering a professional result. Whether youre attaching drywall, installing cabinets, or assembling furniture, self-tapping screws are the perfect tool for the job.

So, the next time youre working on a project, consider reaching for self-tapping screws. Youll be glad you did!